1、Turn Off the Machine: Ensure the machine is powered down and disconnected from the power source before cleaning to prevent accidents.

2、Remove Debris: Use a soft brush or compressed air to remove loose debris from the brush head and other accessible parts. Avoid using water or solvents that could damage the brushes or machine components.

3、Inspect Brushes: Regularly inspect the condition of the brushes. Look for signs of wear, such as frayed bristles or uneven wear patterns. Replace worn brushes promptly to maintain effective performance.

4、Check Mechanical Parts: Inspect belts, gears, and bearings for signs of wear or damage. Lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

5、Use Recommended Lubricants: Always use lubricants specified by the machine manufacturer. Using the wrong type of lubricant can cause damage and reduce the machine's lifespan.

6、Scheduled Lubrication: Establish a regular lubrication schedule based on the manufacturer's recommendations and the machine's usage intensity. Over-lubrication can be as detrimental as under-lubrication, so follow the guidelines precisely.

7、Lubrication Points: Identify all lubrication points, including bearings, gears, and moving joints. Clean these points before applying fresh lubricant to prevent contamination.

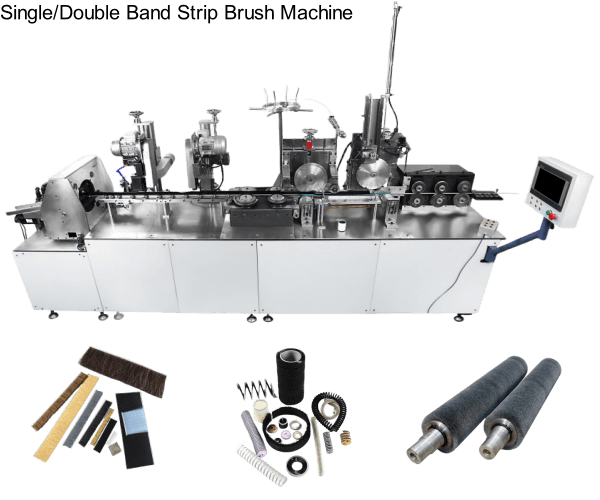

8、Regular calibration and adjustments are necessary to maintain the precision and effectiveness of strip brush machines. Key areas to focus on include:

9、Brush Height and Pressure: Ensure the brush height and pressure are correctly set according to the manufacturer's specifications and the requirements of the task at hand. Incorrect settings can lead to inefficient cleaning and potential damage to surfaces.

10、Alignment: Check the alignment of the brush head and other moving parts. Misalignment can cause uneven wear and reduce the machine's effectiveness.

Finally, kpt reminds you to remember Track the machine's performance over time. Note any changes in efficiency, noise levels, or operational issues. This information can help identify potential problems early and facilitate timely maintenance.